Table of Contents Show

A Guide on How to Fix Cracks in Sheetrock

The interior walls and ceilings of modern homes are finished using panels of sheetrock, that is quite easily cracked by being subjected to blow from a sharp or heavy object. Repair of most cracks is a simple job for the average DIY person, and when sanded down and painted, are barely noticeable.

Introduction to Sheetrock

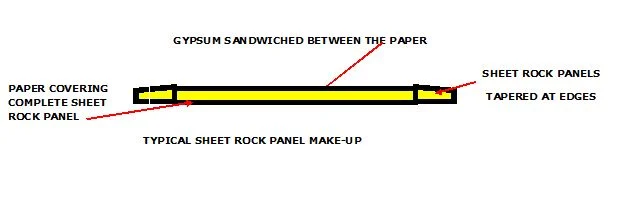

Sheetrock, also known as gypsum board, plasterboard, and wallboard, is used to finish the interior walls and ceilings of buildings and homes in countries throughout the world.

Before sheetrock was invented, thin wooden lathes were attached to the walls, and then up to three coats of plaster were applied; this was known as lathe and plaster. However, as anyone who has had to repair, remove or attach any items to plaster wall knows, sheetrock is a vast improvement.

The sheetrock panels are screwed to the wooden studs on partition walls and ceilings, giving them an overall uniform and smooth finish.

This is an article on DIY and in particular how to fix cracks in the sheetrock, we begin by having a look at the different types of sheetrock available and their purposes.

Different Types of Sheetrock and Their Purposes

Normal Use

- 1/4″ and 3/8” thick sheets are for normal use

- These can be purchased in mold-resistant sheets in damp areas.

Fireproofing Insulation and Soundproofing

- 1/2” and 5/8” thick sheets rated as Type X are used for these requirements.

Foiled Backed Sheets

- All the above types can be supplied in foil-backed form, this type is used where dampness is suspected and prevents the ingress of dampness through the sheetrock panels.

- All the sheets come in 48” (1200mm) widths in various lengths and are tapered at the edges to facilitate taping once fitted to the walls and ceilings.

How to Fix a Crack in Sheetrock

Gather the tools you will need:

- Fillers – This can be in powder form to mix with water or a tub of ready-made fillers. I have used both with equal success, although the powder type keeps a bit longer, the tub of ready-made dries out rather quickly when stored in the garage

- Utility Knife – Fit a new blade to the knife before using

- Metal Scraper – Used to spread the filler over the crack

- Mesh – Specialist mesh, very thin plastic flexible mesh

- Sandpaper – Sandpaper or sander

- Dustcover – Put below the area to be filled.

The repair method is as follows:

- Use the utility knife to open up the crack, leaving a small paper and dust-free groove around the crack. This is to hold the mesh in place.

- Cut the mesh to the size of the crack and apply it across the area, making sure the mesh fits into the grooved edges.

- Using the scraper, carefully apply a thin layer of filler over the mesh and surrounding area of the sheetrock, smoothing over and removing any excess filler.

- Once dry, give the area a quick hand-sanding, then repeat this operation leaving it to dry for at least 12 hours. The filler instructions will probably say ready to sand in 2 or 3 hours; it is better in my experience to leave it for 12 hours to ensure the filler is set, especially if using a power sander.

- Final sanding – start with medium-grade sandpaper and finish with a fine grade.

Summary

Sheetrock is probably better known as gypsum board, plasterboard or wallboard, and is fitted to internal walls and ceilings in all types of buildings and houses.

The sheetrock is easily fitted to the studs in the wall by nails, then the joint edges are taped over, filled, and sanded down.

The sheets can be thin and quite brittle and easily cracked. However, the average DIY person can fix cracks in sheetrock using a selection of hand tools along with crack repair mesh and fillers. Once dry, the area can be sanded down using increasingly fine sandpaper, blending in with the rest of the sheetrock panel.

Fixing Cracks in Sheetrock and Sheet Attachment to Stud Wall